Kitchener Items "Made in Portugal"

What makes the Portuguese textile industry unique is the fact that all segments of the value chain can be found in the northern region around Braga and Porto, this concentration of "know-how", the local proximity and the associated short distances give it a great competitive advantage.

Zur deutschen Version HIER

There are around 6000 companies in Portugal working in all sub-sectors of the textile industry, from spinning and dyeing to fabric manufacturing and ready-to-wear. The Portuguese textile industry dates back to the 18th century, when cotton and linen manufacturers developed the skills and technology to produce quality clothing at a lower cost than most of their European counterparts.

We take this trip as an opportunity to visit our production facility. We eagerly make our way along the coast to the heart of Portugal's textile production to get to know modern textile production up close and to find out first-hand how the textile market has changed in the years since coronavirus, when production has increasingly returned to Europe.

On site, we are welcomed by Sara, who is responsible for our production. She leads us to the women who are working on sewing machines to produce sweaters. Textile manufacturing is largely a female profession, Sara explains. Everything is cut, packed and quality checked.

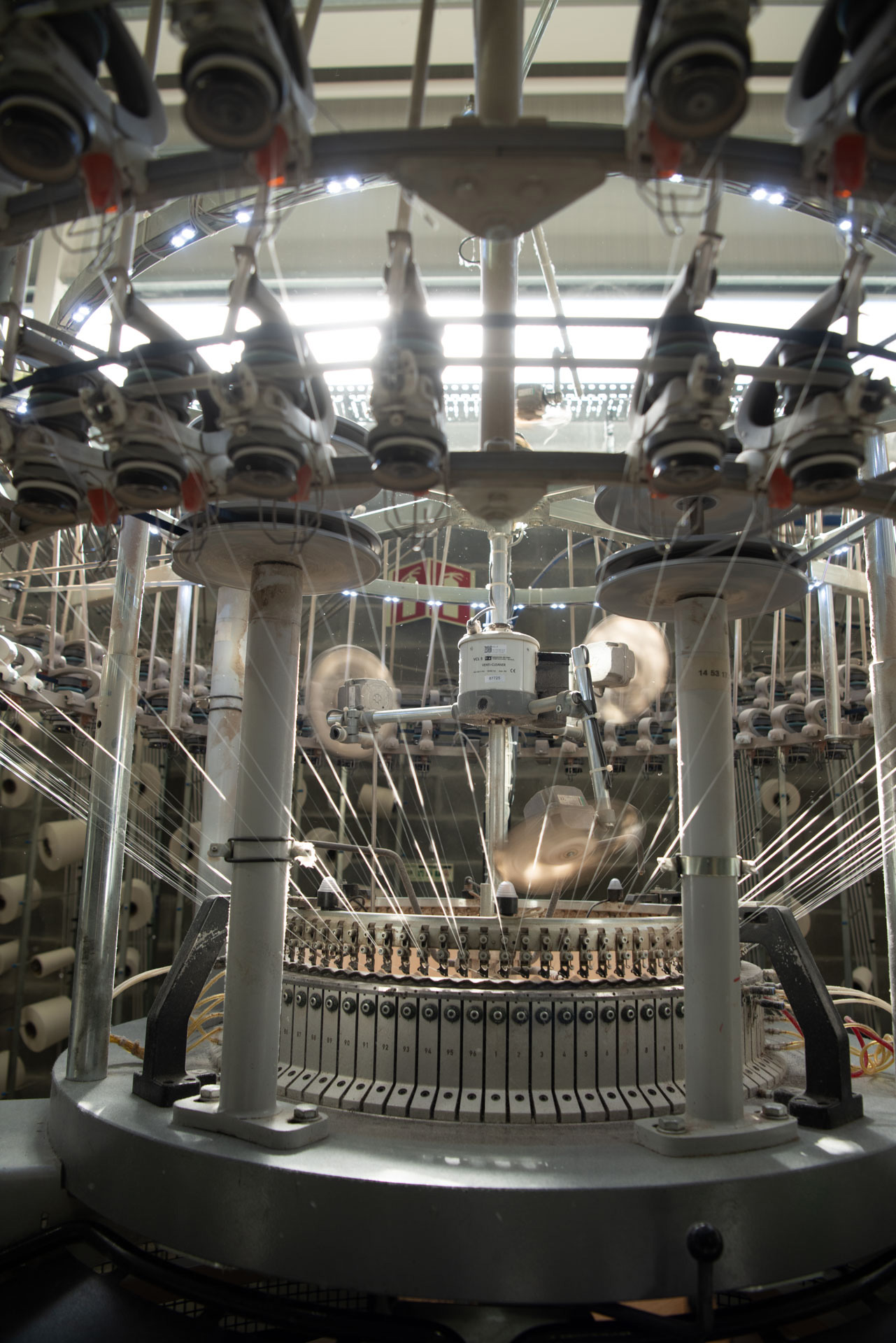

The order situation is very good, says Sara, but it is difficult to find good people. The young Portuguese no longer want to work in the textile industry. More and more companies are having to close due to a lack of staff. The price pressure is high and small productions like ours are hardly economically viable any more. In the hall next door, fabric is being produced on large circular knitting machines. It is an impressive sight to see the large machines that produce, among other things, the striped jersey fabric for our T-shirts. They remind us a bit of aliens. There are around 20 of these machines in the large hall.

On our tour, Sara tells us that before the start of the war in Ukraine, unlike in ready-to-wear, there was shift work here. Production took place here 24 hours a day. This part of production has been greatly expanded in recent years. Today, only two of the machines are still running here. Demand has collapsed since the start of the war, she says. She doesn't know why, as she works in ready-to-wear over there and doesn't know her way around here very well. She suspects that the increased costs have probably led many companies to produce more in Asia or China again.

Pictures Raffael Waldner