A visit to the Burel factory

It is still early morning when we set off away from the Costa Nova, a pretty fishing village with striped houses behind the dunes, the endless sandy beach and the roar of the Atlantic. The journey takes us towards Serra da Estrela, a national park in the interior of the country. There we want to visit the Burel production. We have had Burel wool blankets and scarves in our range for several years.

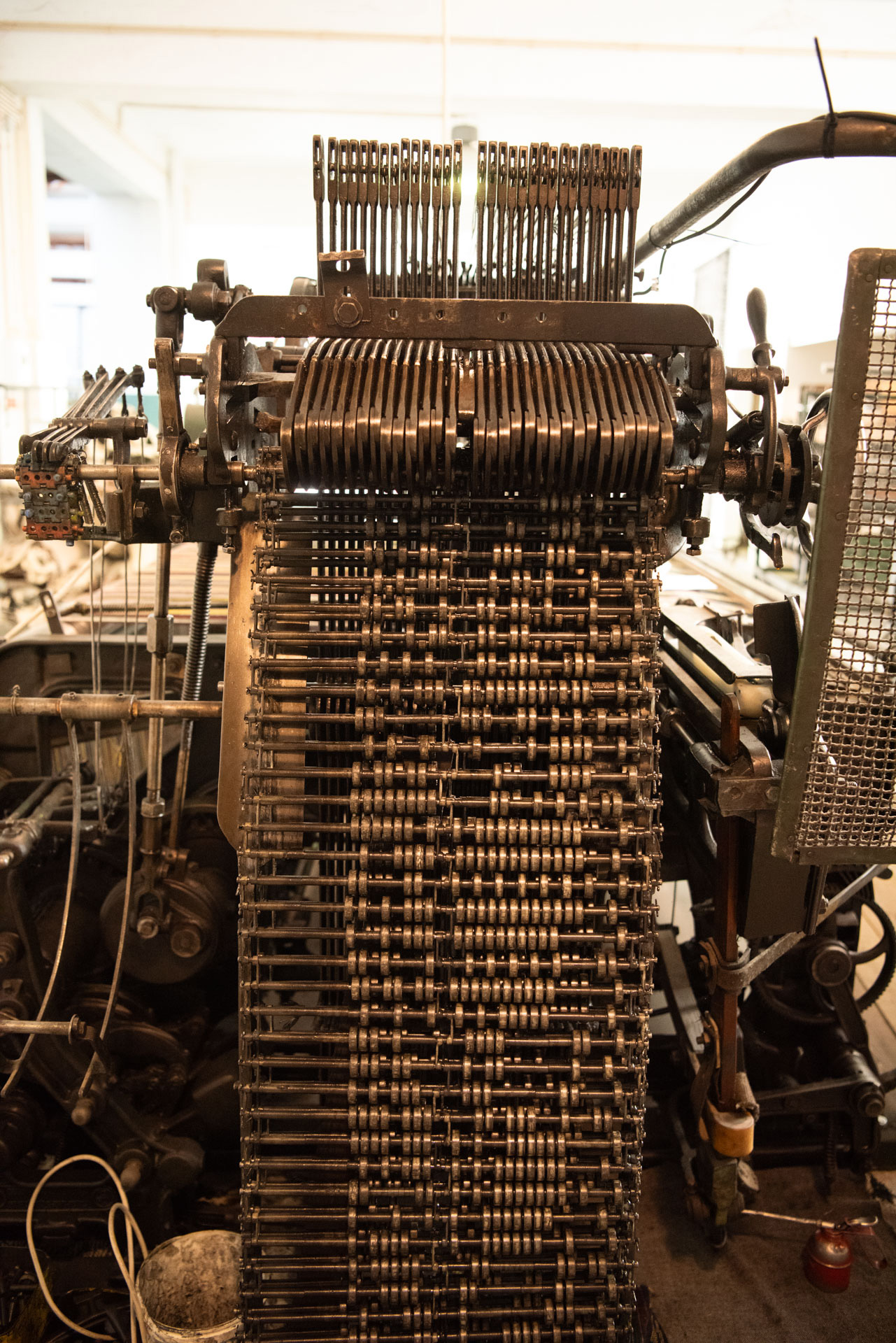

Spinning machine

Spinning machine

Auf Deutsch LESEN

After leaving the fairly densely populated area near the coast behind us, we drive through eucalyptus forests. The road slowly climbs and the vegetation becomes increasingly wild. Large round boulders are scattered across the barren landscape. At some point we reach an altitude of over 1200 meters above sea level and the road begins to flatten out again. It then descends steeply towards Manteigas. The road is spectacularly winding, even by Swiss standards. Unfortunately, we miss the shortcut into the valley. It is impossible to turn around on the narrow, winding road. So we patiently wind our way down towards Manteigas, not for the faint-hearted but certainly the dream of all ambitious cyclists.

The Burel production facility is located in the middle of the village on the Rio Zezere. This is where Isabel Costa founded Burel together with her husband João Tomás. Burel's mission is to preserve and revitalize the industrial heritage and deep knowledge of the wool industry that has lasted for generations and the unique culture and traditions, the people and their history that characterize this place.

Tired of their careers, they decide to open a hotel in the Serra da Estrela. The hotel was to be characterized by the region's artisan traditions. This is how they discovered the Lanifícios Império factory and its Burel fabric, which is now an integral part of all Burel hotels.

Burel fabric is not unlike loden as we know it from the mountainous regions of Central Europe. A material that is first woven and then felted. It was prized by the peasant population of Europe for its durability and its resistance to wind and rain. The sheep of the Serra da Estrel are somewhat similar to our black-nosed sheep. Their long and coarse hair is not suitable for fine fabrics, but is ideal for the Burel.

Quality control

Quality control

Wool cleaning and preparation for spinning

Wool cleaning and preparation for spinning

Details of the oldest loom in the Burel factory

Details of the oldest loom in the Burel factoryDuring the construction of their hotel, Casa das Penhas Douradas, Isabel and her husband realized that the factory was on the verge of insolvency and was no longer able to adapt to the times and current needs. They did not want to allow their textile heritage to simply disappear. And so, without further ado, they decided to buy the factory. When a company goes bankrupt, there is usually not much time to preserve the knowledge. The craftspeople are often about to retire and the machines will be melted down sooner or later.

So the Costas left their jobs in Lisbon behind for good and set about renovating the factory. First of all, the old master weavers had to be convinced to stay in order to pass on their knowledge to a younger generation. At the same time, the old traditional patterns from the weaving books had to be rediscovered and ideas for new designs and products had to be developed on the old looms. Above all, however, they brought new color to the burel, because the fabric had previously only existed in the original colors of the wool.

Back to our factory visit: after the welcome, we follow Isabel into the large production hall and are speechless at first. Pale light falls through the ceiling windows into the large room and it is loud, very loud. A man with headphones is working on looms from the early twentieth century. Every time the "shuttle" hits the edge of the iron loom, there is a loud bang. We start our tour with the oldest looms. They were manufactured in Porto and date back to the 19th century. Although these machines are the oldest, they are also the ones that can weave the most detailed patterns.

“Basically, we are recoverers of material and immaterial heritage. That's our mission. Without a past we have no future. We want to value it with innovation, which is what really matters.”

Isabel Costa

The tour continues through textile history, past machines from the early 20th century to more modern computer-controlled looms. At the back of the hall, a man operates a gigantic machine with long rows of spindles. It moves slowly back and forth like a dance and the wool is spun onto the spindles.

In a second room, wool is delivered, washed and cleaned in equally archaic machines. Isabel demonstrates each of the machines to us with great passion. It's hard to put into words what goes through your mind in these rooms. History can be experienced and felt. We are fascinated.

In a side room with large windows, women sit behind mountains of fabric. They are mending mistakes made during weaving by hand. At sewing machines, women are working on new three-dimensional patterns. Burel fabric is also known for its excellent sound and heat insulation properties and is often used in interior design.

An entire room is dedicated to the old patterns, here are hundreds of fabric samples in all colors and qualities. And that's just a fraction. Many of the patterns are still in boxes as "web code" and are waiting to be discovered. If we had come here two days earlier, we would have met André and Jose from the Portuguese fashion label La Paz. They always work with Burel fabrics for their winter collections.

In 2021, the Burel team was surprised by the news that one of the most important wool processing factories in Covilhã was also facing bankruptcy. They decided to intervene and acquired the factory to give continuity to one of the most important industries in the city, while owning the entire wool processing process, from dyeing to finishing. Processes that are crucial for a Burel to be a Burel.

At the end of our tour, we are particularly surprised by what motivates a person to get involved in such a project. They had repeatedly told their children that if you want to change something, you have to do something and not just talk about it. Burel was their call to action, says Isabel. Then she sighs and says that it takes an infinite amount of strength to realize such a project. One of her looms produces a tenth of a modern machine. There is not much money to be made from it and there is no support from the government. But together with the hotels, the stores in Lisbon and Porto, it somehow adds up.

Before we make our way back to Porto, we have a cup of tea in their Panorama Hotel and admire the fabric in all its different variations on the wall, as furniture, as ceiling installations.

The Burel employees are always creating new three-dimensional patterns which are used in interior design.

The Burel employees are always creating new three-dimensional patterns which are used in interior design. A loom from the 19th century.

A loom from the 19th century.

“We promote and elevate the culture of an inland region, generating jobs and attracting skilled labour to the region, encouraging its economic and social development. ”

Isabel Costa

Burel Hotel CASA DE SÃO LOURENÇO

Burel Hotel CASA DE SÃO LOURENÇOPhotes Raffael Waldner